Products

Contact Us

Zip Code: 252000

Add: Room 1005, Floor 10, Building 5, International Financial Center, Liaocheng Economic And Technological Development Zone, Shandong Province, Prc

40Cr Alloy Steel

40Cr alloy steel delivers high strength, wear resistance, and impact toughness—ideal for heavy-duty gears, shafts, and structural parts requiring durability and precision.

Key words:

Detail

Product Description:

40Cr alloy steel is a medium carbon chromium steel widely used for its excellent strength, toughness, and hardenability. It performs well after quenching and tempering, achieving high mechanical strength and good fatigue resistance. With stable processing performance and uniform microstructure, 40Cr is ideal for manufacturing high-load, wear-resistant mechanical parts.

This material offers good machinability and dimensional stability, with minimal deformation during heat treatment. It is commonly applied in the production of gears, shafts, axles, bolts, spindles, and other transmission components. In automotive, construction machinery, and heavy equipment manufacturing, 40Cr is favored for its balance between toughness and wear resistance.

After proper quenching and tempering, the surface hardness of 40Cr alloy steel can reach 55–60HRC. It also exhibits high fatigue strength and impact resistance, ensuring long service life under cyclic or heavy loads. With optional surface treatments like nitriding or induction hardening, its wear and corrosion resistance can be further improved for demanding working environments.

Parameter:

| Alloy Designation | Main Component(%) | ||||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | Ti | more | |

| 20Cr | 0.18~0.24 | 0.17~0.37 | 0.5~0.8 | ≦0.03 | ≦0.03 | 0.7~1.0 | ≦0.03 | ≦0.03 | ≦0.01 | – | – |

| 40Cr | 0.37~0.44 | 0.17~0.37 | 0.5~0.8 | ≦0.035 | ≦0.035 | 0.8~1.1 | ≦0.03 | ≦0.03 | ≦0.15 | – | – |

| 20CrMnTi | 0.17~0.23 | 0.17~0.37 | 0.8~1.1 | ≦0.035 | ≦0.035 | 1.0~1.3 | ≦0.03 | ≦0.03 | ≦0.15 | 0.04~0.1 | – |

| 35CrMo | 0.32~0.4 | 0.17~0.37 | 0.4~0.7 | ≦0.035 | ≦0.035 | 0.8~1.1 | ≦0.03 | ≦0.03 | 0.15~0.25 | – | – |

| 42CrMo | 0.38~0.45 | 0.17~0.37 | 0.5~0.8 | ≦0.035 | ≦0.035 | 0.9~1.2 | ≦0.03 | ≦0.03 | 0.15~0.25 | – | – |

| Gr15 | 0.95~1.05 | 0.15~0.35 | 0.2~0.4 | ≦0.027 | ≦0.02 | 1.3~1.65 | ≦0.03 | ≦0.25 | – | – | Ni+Cu≤0.5 |

| 65Mn | 0.62~0.7 | 0.17~0.37 | 0.9~1.2 | ≦0.035 | ≦0.03 | ≦0.2 | ≦0.3 | ≦0.25 | – | – | – |

| 70# | 0.67~0.75 | 0.17~0.37 | 0.5~0.8 | ≦0.035 | ≦0.035 | ≦0.25 | ≦0.3 | ≦0.25 | – | – | – |

| 45CrNiMo | 0.42~0.49 | 0.17~0.37 | 0.5~0.8 | ≦0.035 | ≦0.035 | 0.80~1.10 | – | – | 0.20~0.30 | – | V:0.10~0.20 |

Package:

Packed in waterproof paper and wooden boxes.

Application description:

Due to properties such as high strength and corrosion resistance, alloy steel is widely used in four core fields, as detailed below:

1. Industrial Manufacturing

Mechanical Components: Quenched and tempered steels such as 40Cr, featuring impact resistance and heavy load resistance (e.g., gears, shafts).

Mold & Tooling: Cold-work die steel like Cr12 and hot-work die steel like H13, with high temperature resistance and wear resistance.

Bearings: High-carbon chromium steel such as GCr15, offering high hardness and fatigue resistance.

2. Energy & Chemical Industry

Oil & Gas Sector: 316L stainless steel and nickel-based alloys like Inconel 625, with acid-alkali resistance and high pressure resistance.

Power Sector: 12Cr1MoVG heat-resistant steel (for thermal power) and SA508 low-alloy steel (for nuclear power), providing high temperature resistance and radiation resistance.

Chemical Equipment: 2205 duplex steel and Hastelloy, enabling strong corrosion resistance (e.g., reaction kettles).

3. Transportation

Automotive: Q&P high-strength steel (for car bodies) and 45MnB alloy steel (for crankshafts), realizing lightweight and impact resistance.

Rail Transit: Q450NQR1 weathering steel (for carriage bodies) and CL60 bainitic steel (for axles), with corrosion resistance and wear resistance.

Aerospace: 300M ultra-high strength steel (for landing gears) and GH4169 superalloy (for engine blades), resisting extreme stress.

4. Military & Special Scenarios

Weaponry: Homogeneous armor steel (for tanks) and D6AC high-strength steel (for artillery shells), with armor-piercing resistance and explosion resistance.

Extreme Environments: 9Ni low-temperature steel (for polar equipment) and TC4 titanium alloy (for deep-sea detectors), offering low-temperature resistance and seawater corrosion resistance.

About Us

Shandong Xiangtong Huiyuan Metal Materials Co., Ltd. is a trading company under the factory of Shandong QianHai metal material CO, LTD manufacturing company ,which is specializing in this field for many years. Sales to various fields at home and abroad(cars, motorcycles, industrial machinery, Bridges, railways, etc.

In order to adapt to the changing requirements,our company is positive for technical innovation. We'll try our best to become the leading enterprise for era of globalization. Thank you!

Quality Assurance

We strictly produce and inspect steel in accordance with international standards. All steel undergoes composition analysis, mechanical property testing, and visual inspection before shipment. We also provide third-party inspection reports (SGS/BV, etc.). This ensures consistent quality in every batch and meets customer project requirements.

Fast Delivery

We maintain ample inventory and can ship within approximately 15 days. We support rapid deployment of various specifications and ensure prompt delivery upon order confirmation. We partner with multiple logistics companies to ensure on-time delivery.

Customization Available

We offer steel in a variety of specifications and materials, and we support custom cuts, surface treatments, and special material customization to meet your individual needs.

After-Sales Guarantee

We are committed to providing comprehensive after-sales service. We offer returns and exchanges for quality issues, and provide technical support and user guidance to ensure a worry-free business relationship.

- Eco-Friendly Options: We also offer eco-friendly packaging materials upon request. Please contact us if you prefer this option.

- International Shipping: For international orders, we comply with all customs regulations and ensure proper documentation is included.

- If you have any specific packaging requirements, please let us know, and we will do our best to accommodate your needs.

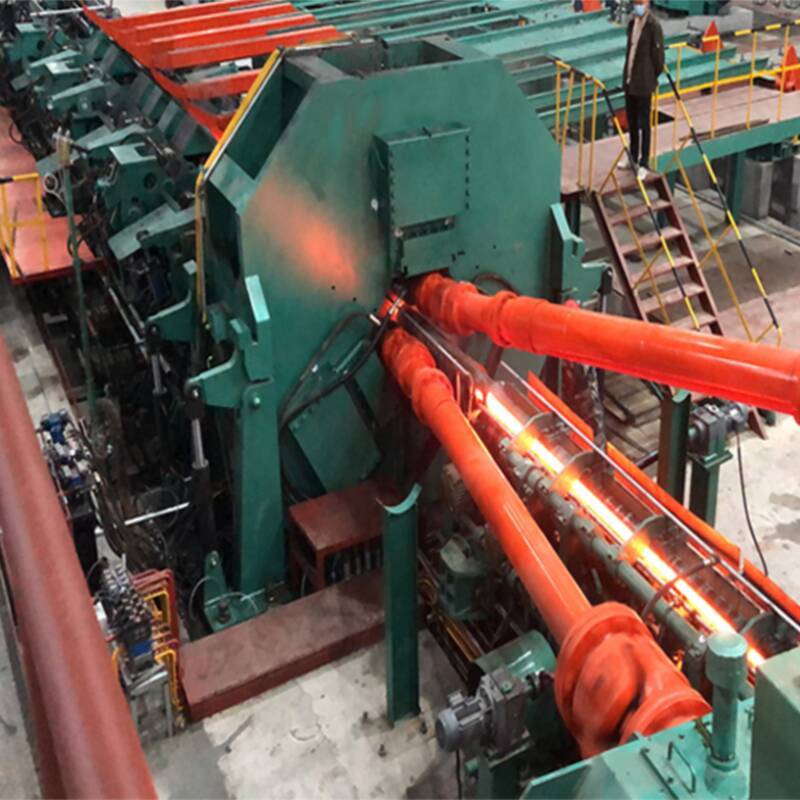

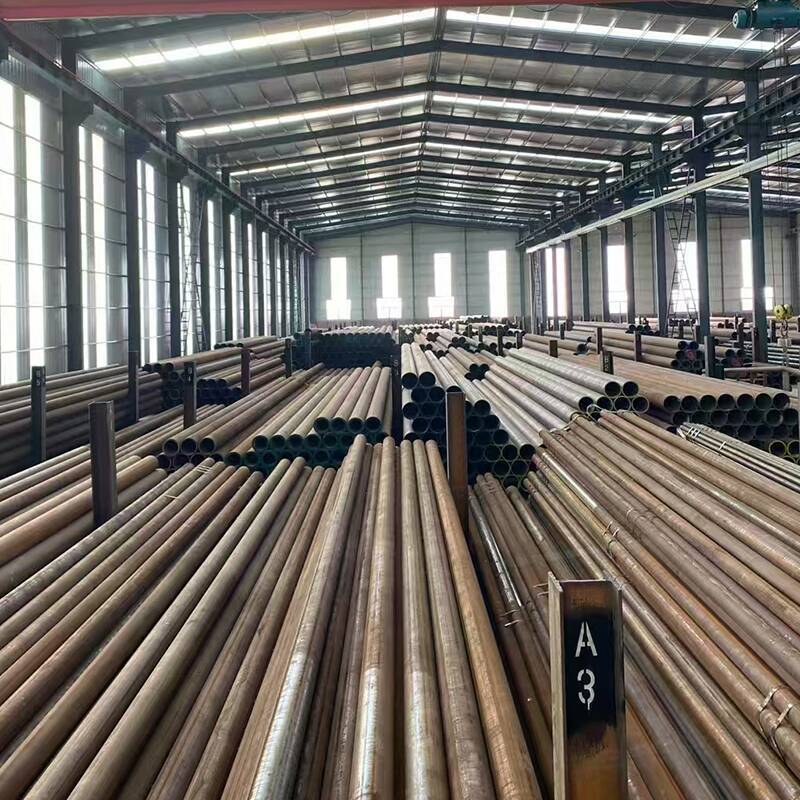

Factory

Inquiry

Please fill in the contact information and your needs, we will arrange professionals to contact you!

FAQ

Q

Can you send samples?

A

Of course, We can provide samples for buyer's testing free of charge, but buyers need to pay for shipping costs.

Q

What product information do I need to provide?

A

Please kindly provide the material, OD, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q

It's my first time to import steel products, can you help me with it?

A

Sure,we have agent to arrange the shipment, we will do it together with you.

Q

What about product prices information?

A

Prices various according to periodic price changes of raw materials.

Q

What ports of shipment are there?

A

Any port in China (Tianjin Qingdao Shanghai)

Q

What is your terms of payment ?

A

100% IRRECOCABLE L/C AT

30% T/T IN ADVANCE ,70% T/T BALANCE AT THE SIGHT OF COPY B/L.