Hollow Anchor Bar: Engineering Stability for Underground and Geotechnical Applications

Release time:

2024-08-23

A Hollow Anchor Bar (Hollow Rock Bolt) is a high-strength, tubular steel reinforcement system designed for ground stabilization in geotechnical and mining engineering. Featuring a central hollow channel for grout injection, it combines load-bearing capacity with efficient installation, making it ideal for securing unstable rock masses, slopes, and underground structures.

Product Overview

A Hollow Anchor Bar (Hollow Rock Bolt) is a high-strength, tubular steel reinforcement system designed for ground stabilization in geotechnical and mining engineering. Featuring a central hollow channel for grout injection, it combines load-bearing capacity with efficient installation, making it ideal for securing unstable rock masses, slopes, and underground structures.

Key Features

Tubular Design: Central bore enables simultaneous drilling, anchoring, and grouting, reducing installation time.

High Load Capacity: Made from alloy steel (e.g., Grade 500/700) or stainless steel, with yield strength up to 1,100 MPa.

Corrosion Resistance: Optional hot-dip galvanizing or epoxy coatings for harsh environments.

Threaded Ends: Compatible with plates, nuts, and couplers for modular assembly.

Core Advantages

Rapid Installation: Integrated drilling-grouting process minimizes downtime in tunneling or mining operations.

Enhanced Bonding: Grout fills the hollow core and surrounding fissures, creating a unified reinforcement system.

Adaptability: Suitable for weak rock, soil, or fractured zones where traditional anchors may fail.

Real-Time Monitoring: Permits post-installation grout replenishment or pressure testing.

Applications

Tunnel Boring: Stabilizes excavation faces in rail, road, and hydropower tunnels.

Slope Stabilization: Prevents landslides in highway cuttings or natural terrains.

Mining Shafts: Reinforces roof and walls in underground coal/metal mines.

Underground Structures: Secures parking garages, metro stations, and deep foundations.

Technical Specifications

Diameter: 25mm – 51mm (customizable)

Length: 1m – 12m (standard or tailored)

Standards: ASTM F432, ISO 16047, or project-specific certifications.

Why Choose Our Hollow Anchor Bars?

Certified Quality: Third-party tested for tensile strength, elongation, and fatigue resistance.

Custom Solutions: Adjustable grout ports, hybrid materials (e.g., fiberglass composite), and anti-seismic designs.

Global Compliance: Meets EU, US, and Asian safety regulations for infrastructure projects.

Previous

Previous

BLOGS

China's Steel Industry in March 2025: Policy-Driven Recovery Amid Global Uncertainties

The 17th China Steel Summit Forum (March 21–22, Zhengzhou) gathered over 2,000 industry leaders to discuss topics like smart manufacturing and green transitions6. Additionally, regional forums in Northeast and Southwest China addressed localized challenges. For example, the Northeast Steel Industry High-Quality Development Forum (March 26, Shenyang) emphasized digitalization and new opportunities in renewable energy projects

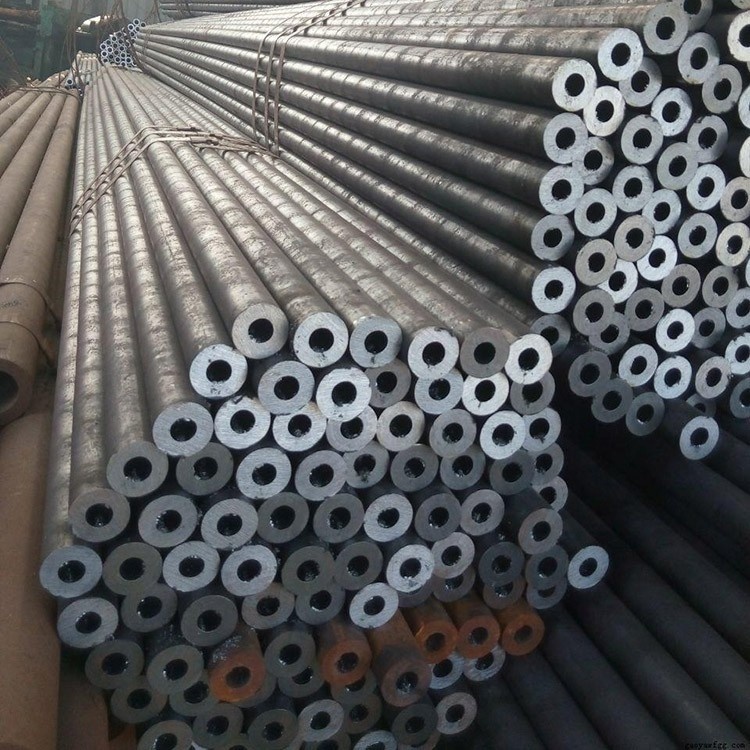

Seamless Steel Pipes: Versatile Solutions for Modern Industries

Seamless steel pipes, known for their durability and high performance, are indispensable across various industries. Their lack of welded seams ensures superior strength, pressure resistance, and reliability in demanding environments. Below, we explore key applications of seamless steel pipes and their critical role in advancing industrial operations.

The Foreign Trade Metal Industry: Breaking Through Difficulties and Opening up New Prospects

In conclusion, despite the challenges, the foreign trade metal industry is brimming with potential. Shandong Xiyang Metal Materials Co., Ltd. is well - positioned to capitalize on these opportunities, thanks to our strategic partnerships, technological prowess, and customer - centric approach. We are committed to continuing our innovation drive and providing value - added services, with the aim of leading the industry into a new era of growth and prosperity.

Stainless steel application field: innovation-driven, diversified expansion

In the current global industrial panorama, the versatility and reliability of stainless steel have rendered it an indispensable material across a vast spectrum of applications. Shandong Xiyang Metal Materials Co., Ltd. has been at the forefront of harnessing the potential of stainless steel, propelling its usage into new frontiers.

Carbon steel pipe. This is a common steel pipe material that includes steels with different carbon contents (low carbon steel, medium carbon steel, and high carbon steel). This type of steel pipe is usually used to transport fluids such as water and gas, and to make machine parts.

Welding connection is a common way to connect steel pipes. The connection is achieved by heating the steel pipe interface to melt the welding rod and fuse it with the steel pipe. This connection method has the advantages of firm connection, good sealing, good durability, low cost, and no need for frequent maintenance.