What is Aluminum Strip

Release time:

2024-09-30

Aluminum strip, a thin, flat-rolled product made from aluminum alloys, is a cornerstone material in modern manufacturing and engineering. Known for its lightweight nature, corrosion resistance, and excellent conductivity, it is widely used in industries ranging from packaging to electronics. Available in varying thicknesses, widths, and tempers, aluminum strips are tailored to meet specific performance requirements.

Aluminum strip, a thin, flat-rolled product made from aluminum alloys, is a cornerstone material in modern manufacturing and engineering. Known for its lightweight nature, corrosion resistance, and excellent conductivity, it is widely used in industries ranging from packaging to electronics. Available in varying thicknesses, widths, and tempers, aluminum strips are tailored to meet specific performance requirements.

Key Applications

Construction & Architecture

Used in roofing, cladding, and HVAC systems due to its lightweight nature and resistance to environmental degradation. Anodized or painted strips provide aesthetic appeal for architectural designs.

Automotive & Transportation

Critical for manufacturing lightweight body panels, battery enclosures for EVs, and heat shields. Reduces vehicle weight to enhance fuel efficiency and meet emission standards.

Electronics & Electrical Engineering

Serves as conductive material in transformers, capacitors, and circuitry. Its high electrical conductivity and thermal management properties ensure reliability in consumer electronics and power systems.

Packaging Industry

Forms the backbone of food and pharmaceutical packaging (e.g., foil lids, blister packs). Compliant with hygiene standards, offering barrier protection against moisture, light, and contaminants.

Renewable Energy

Utilized in solar panel frames and photovoltaic system components, combining corrosion resistance with structural integrity to withstand outdoor environments.

Industrial Machinery

Fabricated into gaskets, seals, and heat sinks, where precision thickness and thermal conductivity are paramount.

Previous

BLOGS

China's Steel Industry in March 2025: Policy-Driven Recovery Amid Global Uncertainties

The 17th China Steel Summit Forum (March 21–22, Zhengzhou) gathered over 2,000 industry leaders to discuss topics like smart manufacturing and green transitions6. Additionally, regional forums in Northeast and Southwest China addressed localized challenges. For example, the Northeast Steel Industry High-Quality Development Forum (March 26, Shenyang) emphasized digitalization and new opportunities in renewable energy projects

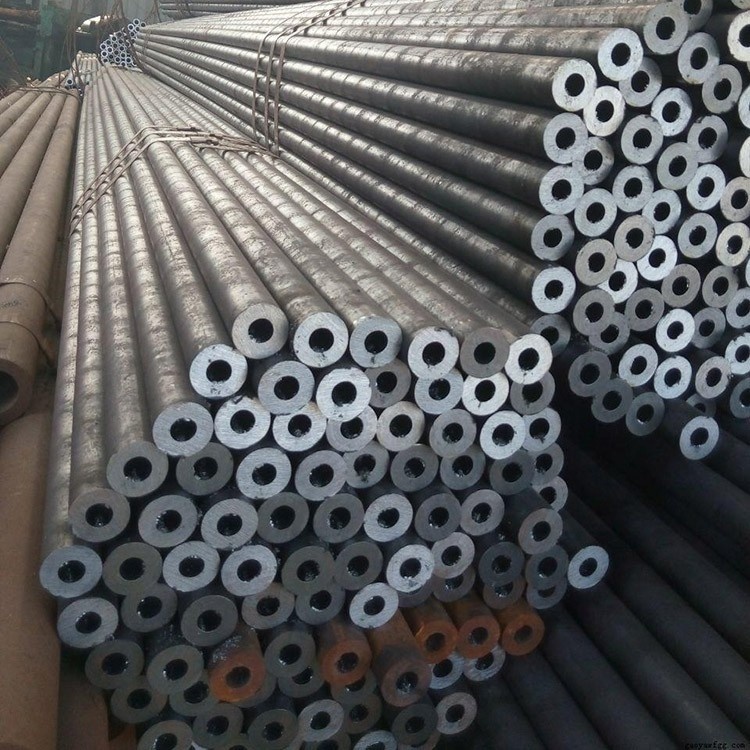

Seamless Steel Pipes: Versatile Solutions for Modern Industries

Seamless steel pipes, known for their durability and high performance, are indispensable across various industries. Their lack of welded seams ensures superior strength, pressure resistance, and reliability in demanding environments. Below, we explore key applications of seamless steel pipes and their critical role in advancing industrial operations.

The Foreign Trade Metal Industry: Breaking Through Difficulties and Opening up New Prospects

In conclusion, despite the challenges, the foreign trade metal industry is brimming with potential. Shandong Xiyang Metal Materials Co., Ltd. is well - positioned to capitalize on these opportunities, thanks to our strategic partnerships, technological prowess, and customer - centric approach. We are committed to continuing our innovation drive and providing value - added services, with the aim of leading the industry into a new era of growth and prosperity.

Stainless steel application field: innovation-driven, diversified expansion

In the current global industrial panorama, the versatility and reliability of stainless steel have rendered it an indispensable material across a vast spectrum of applications. Shandong Xiyang Metal Materials Co., Ltd. has been at the forefront of harnessing the potential of stainless steel, propelling its usage into new frontiers.

Carbon steel pipe. This is a common steel pipe material that includes steels with different carbon contents (low carbon steel, medium carbon steel, and high carbon steel). This type of steel pipe is usually used to transport fluids such as water and gas, and to make machine parts.

Welding connection is a common way to connect steel pipes. The connection is achieved by heating the steel pipe interface to melt the welding rod and fuse it with the steel pipe. This connection method has the advantages of firm connection, good sealing, good durability, low cost, and no need for frequent maintenance.